We use cookies to ensure that we give you the best experience of our website.

By clicking 'Accept' you consent to cookies being place on your computer for analysis of your visit. Please see our Privacy Policy for more information.

During these unprecedented times, Monolution has been working around the clock as part of the Ventilator Challenge UK consortium to produce key components for critical care equipment.

When COVID-19 hit the UK at the beginning of March, the Government estimated that up to 30,000 ventilators might be required to support the lives of critically ill patients. Acknowledging that this figure was far in excess of existing capacity, it called on British manufacturing to help. The Ventilator Challenge UK consortium was quickly established; advanced engineering, industrial and technology businesses from the aerospace, automotive and medical sectors coming together and using their innovative thinking, creativity and combined expertise to support the NHS and help save lives.

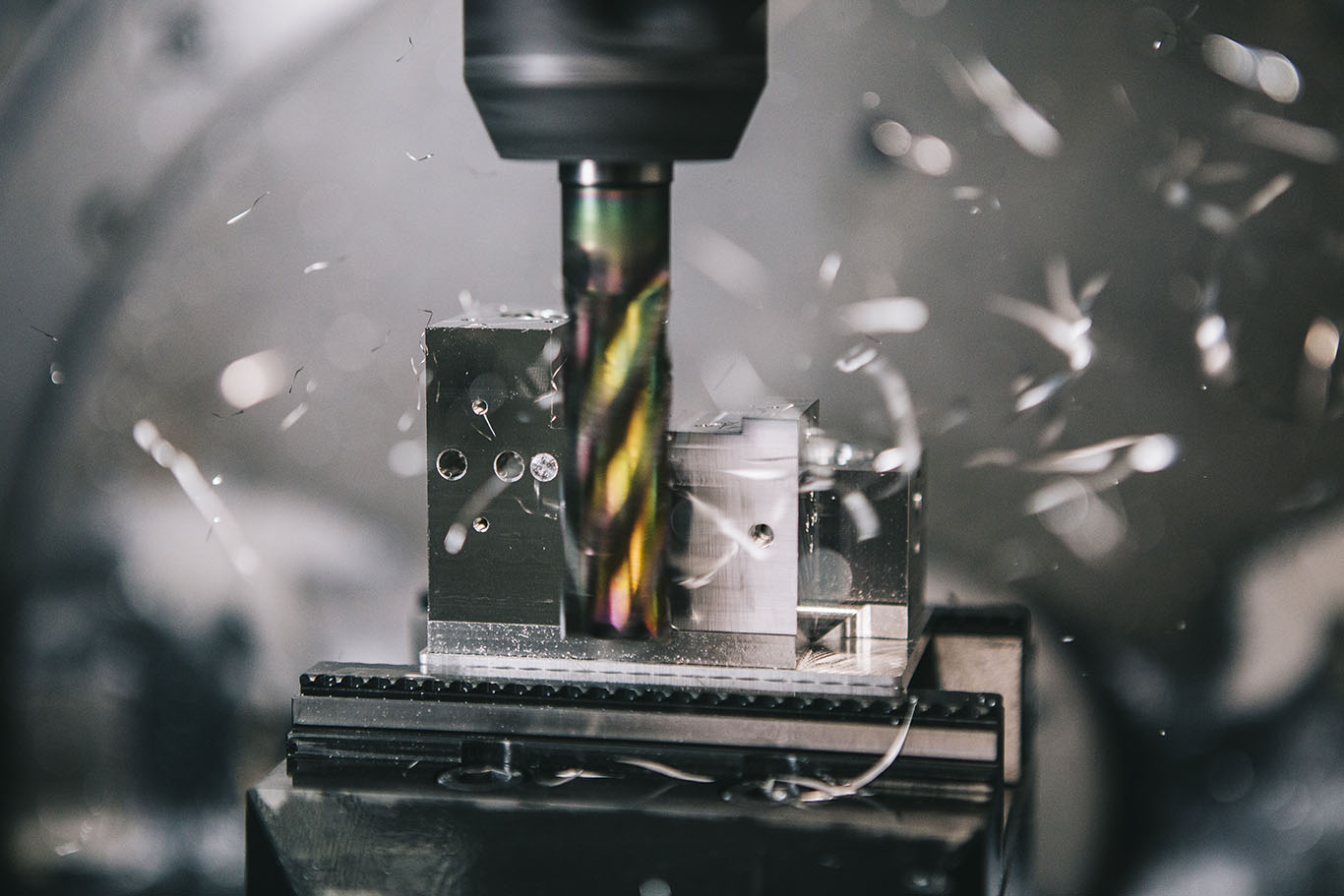

Monolution, which is best known for its CNC machining services and precision engineering in support of FI racing teams and the aerospace sector, has been working alongside McLaren Racing to produce parts for the assembly of the Penlon Prima ESO2 device.

By deploying 22 high-end five-axis machines, the team at Monolution created control blocks, centre plates, absorber docks, mount plates and gas blocks for the Penlon ventilators. Within a week of the Government placing the order, Monolution were delivering their parts and the ventilators were being assembled and tested before making their way to the newly created NHS Nightingale Hospital in East London to be installed.

Using over 15 tons of aluminium and working around the clock from late March to the end of May, meant that thousands of parts were produced each week, with everyone involved personally contributing to saving lives. Monolution Director Dean Cleverley said “‘This is the proudest moment of Monolution’s history and to be able to support our NHS and ultimately help save lives is amazing.”

“The experience we have gained through this unprecedented challenge, the collaborative working with other organisations, the diversification of our skills and the response of our staff have all been incredibly rewarding”.

For Monolution, the first half of 2020 will be remembered as a pivotal time in the company’s development. Whilst revenues from its traditional markets of motorsport and aerospace have been decimated because of the pandemic, there are tentative signs of recovery. Perhaps more significant are the learnings from its involvement in the Ventilator Challenge UK consortium, meaning that Monolution is now able to use recent experience to broaden its offering into the medical industry.

Throughout all of this, Monolution’s Directors have been investing in developing the Company’s brand and its marketing assets. The results of this crucial project, including a new corporate website will be available in the coming months.

For more information about Monolution and its involvement in the Ventilator UK Challenge, please contact – info@monolution3d.com